What Makes a Glass Bottle Top-Notch? Stuff to Keep in Mind

Being the head honcho at a perfume factory, I get how super...

Capacity: 30/50/100ml

Material: High-Clarity Glass

Flexible custom quantity

Capacity: Customizable

Material: Super Flint Glass

Mold Development Cycle: 7-15 days

Capacity: 50/75ml

Features: Extra-thick base, customizable engraving

Ideal for: High-end fragrance brands

Clean lines and high-clarity glass. The ideal choice for modern, unisex fragrances. Flexible custom perfume bottle services are available.

A heavy, solid base that provides a substantial, luxurious hand-feel. Designed for high-end, niche, and luxury perfume brands.

Organic, convention-breaking forms for an artistic and recognizable presence. We can bring your most ambitious, unique perfume bottle designs to life.

With impeccable craftsmanship and premium materials, we match your high-end positioning. We help you create collectible works of art that elevate your brand’s premium.

Leveraging our large-scale capabilities, we offer cost-effective mass production with reliable delivery, ensuring your products can quickly and consistently reach the entire market.

We understand the challenges startups face. Our flexible MOQs and extensive range of stock molds help you achieve a remarkable brand launch, even on a limited budget.

INJECT YOUR BRAND’S DNA INTO EVERY BOTTLE.

Choose from our 8,000+ stock molds, or let us develop an exclusive private label perfume bottle mold for you.

From pure super-flint to gradients, pearlescent, frosted, or crackle effects—let the color of the glass tell your brand's story.

We offer millions of combinations of metal, resin, and magnetic caps and atomizers, ensuring a perfect seal and a premium closure experience.

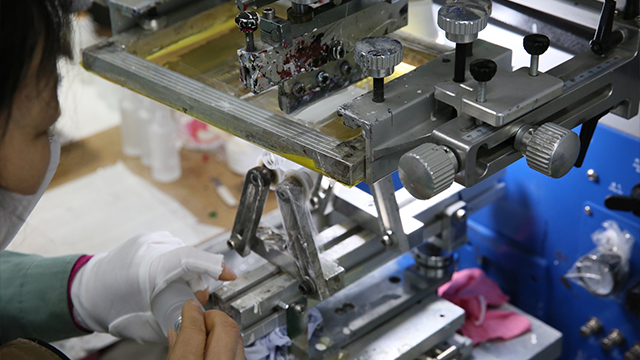

Silk screening, hot stamping, 3D printing, and laser engraving. We present your logo and designs in the most exquisite way.

We provide design and production for matching premium cartons and gift boxes, ensuring a consistent brand experience from the inside out.

Why? Because the craftsmanship for glass bottles, metal pumps, wooden caps, and gift boxes is completely different.

Have you ever juggled 4-5 factories, only to end up with mismatched caps, color variations, and endless delays?

At DAS Group, we solve this. Our 17 factories are specialists in their own fields—glass, injection molding, metalwork, and paper. Through one unified project team, we ensure every component is perfectly matched from day one, with one team accountable to you.

We invite you to see how our 17 member factories work in synergy—from the molten glass in the furnace and the exacting precision of our molds, to the meticulous assembly in our cleanrooms. This is the very foundation of our commitment to delivering one-stop solutions, superior quality, and reliable delivery.

DIFFERENTIATED SERVICES

Tailored services designed for your specific role.

Turn 5 Gantt Charts into 1

Our centralized group production planning eliminates risks of delays.

Our group-level raw material purchasing translates directly into cost savings for you.

Monitor every step in real-time, from mold creation to final shipment.

One contact, one order, all problems solved.

Your Creativity, Unconstrained

Before tooling, our engineers will optimize your design to ensure a flawless production outcome.

Hold a physical model of your product in your hands within 7 days.

Access our latest samples of innovative materials and techniques to spark your creative inspiration.

Turn Your Packaging Into Your Best Salesperson

Save significant management time and communication costs, allowing you to focus on brand and market strategy.

Our integrated group model shields you from supply chain disruptions, ensuring your product hits the shelves on time, every time.

Your core business assets are secured through strict NDAs and exclusive ownership of your private molds.

DIFFERENTIATED SERVICES

PRODUCTION PROCESS SHOWCASE

Why it matters: We source only high-purity silica sand and raw materials from audited suppliers. This prevents microscopic impurities that could cause weakness or cloudiness in the final product.

Why it matters: Raw materials are melted at a precise, consistent temperature (over 1500°C) in our furnaces. This ensures a uniform molten glass composition, which is critical for consistent bottle wall thickness and strength.

Shearing molten glass into gobs of precise weight.

Shaping the bottle in blank and final blow molds.

Why it matters: This is a critical step many low-cost suppliers rush. We slowly cool every bottle in a long oven (Lehr) to eliminate internal stress. This prevents cracking or shattering during customer filling, capping, or transportation.

Applying surface coating to hot bottles for scratch resistance.

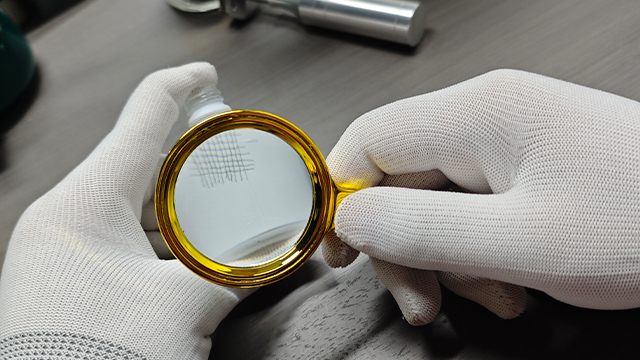

Why it matters: High-speed cameras and lasers inspect every single bottle for dozens of potential defects—like checks, stones, and blisters—that are invisible to the human eye, ensuring your production line receives only perfect containers.

Improving lubricity to prevent scratches on conveying lines.

Applying silk-screening, frosting, or other custom finishes.

Why it matters: After machines do their job, our skilled technicians perform a final visual and tactile inspection. This human touch catches subtle aesthetic issues, guaranteeing the premium look and feel your brand deserves.

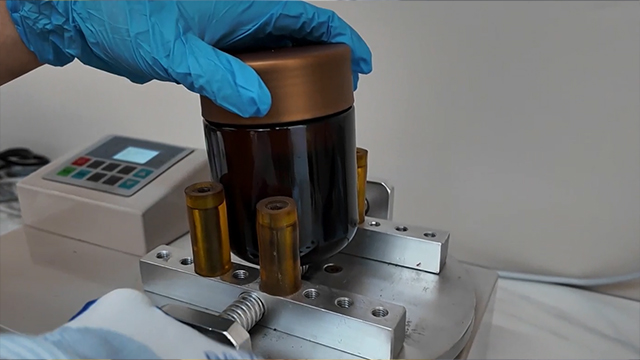

Assembling pumps and caps in a dust-free environment.

Why it matters: Finished products are assembled and packed in a dust-controlled environment. We use robust, layered packaging to prevent breakage and contamination, ensuring they arrive at your facility in pristine, ready-to-use condition.

QUALITY CONTROL

Simulates extreme temperature changes to prevent cracking.

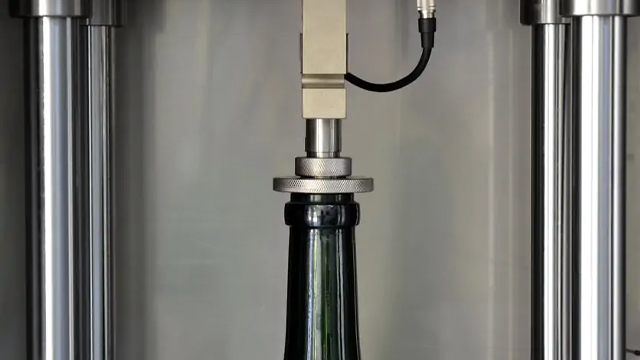

Ensures bottle resistance to pressure during stacking and capping.

Guarantees every bottle precisely matches design specifications.

Ensures product integrity and prevents any form of leakage.

Confirms durability of decorations against scratches and peeling.

Verifies cap fit and seal performance to prevent leaks.

Confirms glass complies with international food-grade standards.

CERTIFICATIONS & BY THE NUMBERS

Products are subject to multiple technical certifications and tests such as ISO 45001,FSC,OHSAS 18001,FSSC 22000,CE, ISO 14001,SGS,ISO 7086-1/2,ISO 22716,GMP,EFSA, USP/EP,ISO 22000,FDA,UKAS,ISO 15378, ISO 9001, and Energy Star every year according to customer requirements, ensuring compliance with international safety, quality, and efficiency standards.

45+

Consider patent protection for each technology to ensure legal protection and market exclusivity.

17

Choose from our 8,000+ stock molds, or let us develop an exclusive private mold for you.

10%

10% of profits are invested annually in the continuous improvement of products.

30+

The defective rate of materials and products is recorded daily. Delivered after passing the test.

DIFFERENTIATED SERVICES

SUSTAINABILITY

EXPLORE MORE PRODUCTS

FREQUENTLY ASKED QUESTIONS (FAQ)

For stock items, our MOQ is typically 5,000 pieces. For custom projects that require a new mold, the MOQ will be higher. However, we offer flexible support policies for startups, so please contact us to discuss the details.

Typically, it takes 3-15 days from design confirmation to the production of the first samples.

Absolutely! That is the core advantage of our one-stop service. We can provide a complete set of components and outer packaging that perfectly match your bottle.

Before mass production, we provide physical samples (and can match to Pantone colors upon request) for your signed approval. We only proceed with large-scale production after your confirmation to ensure zero color deviation.

BLOG

Being the head honcho at a perfume factory, I get how super...

Submit Your Inquiry to DAS-Group,All the Inquiries Will Be Replied Within 20 Minutes

Your email information will be kept strictly confdential and our business staff will ensurethat your private information is absolutely safe!

Tired of Mismatched Components & Delays?

Discover 10 Critical Mistakes to Avoid When Sourcing Your Packaging from China.